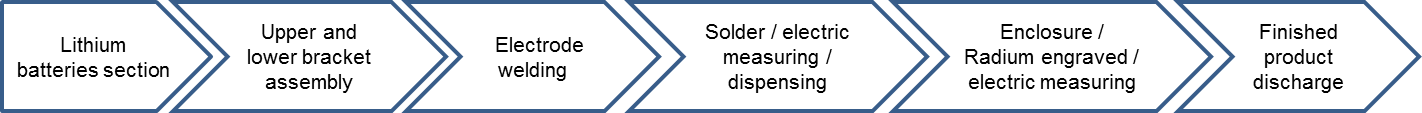

The lithium battery core material is electrically measured and then assembled into a battery assembly and weld electrode connection sheet.

The assembled battery assembly establishes a product Bar code, and records production information.

It has been tested by electrical measurement, automatic solder, automatic dispensing, placement of springs, upper and lower shell assembly, automatic locking screws, finished product electrical measurement and product serial number printing.

1. Use part of manual operations with automatic single machine mode for production line stringing.

2. Connect the factory MES system to perform Bar code monitoring production operation.

3. Load the battery production lot number, and screen according to the voltage and internal resistance.

4. Use resistance welding machine for electrode spot welding, constant current, constant voltage control.

5. Use CCD image system in each process for defect detection.

6. Construct a complete battery automatic test system, perform functional tests in each process, upload the test data to the SHOP FLOOR database, and establish a production history based on the product serial number.

|

Item |

Specification |

|

Production |

Cycle time :30sec/set |

|

Control System |

PC Base |

|

Compressed Air System |

5~7 kgf/cm |

|

Power System |

50 ~ 60HZ 1PH 220V |

|

Batteries Model |

18650、20650、20700、21700 |